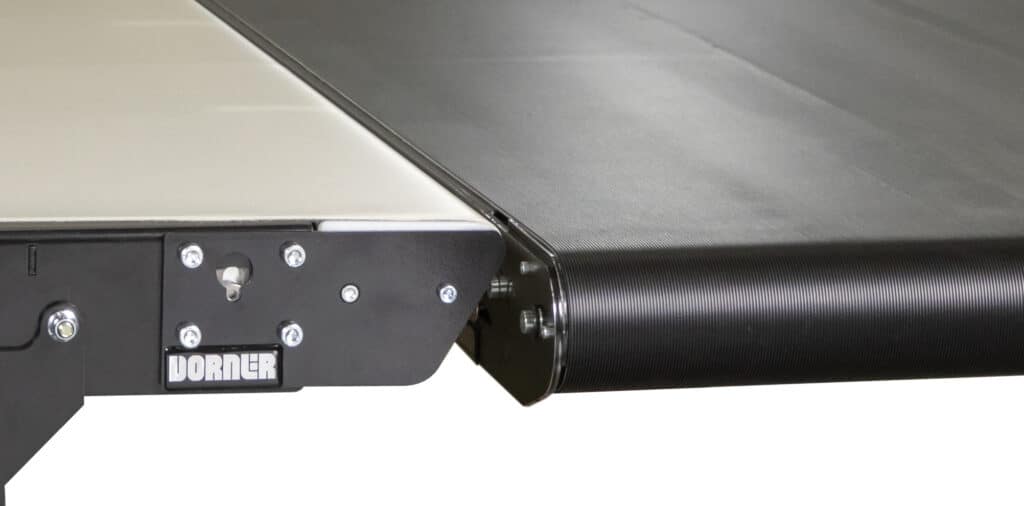

DCMove Belted Conveyor

Benefits of DCMove Belted Conveyors:

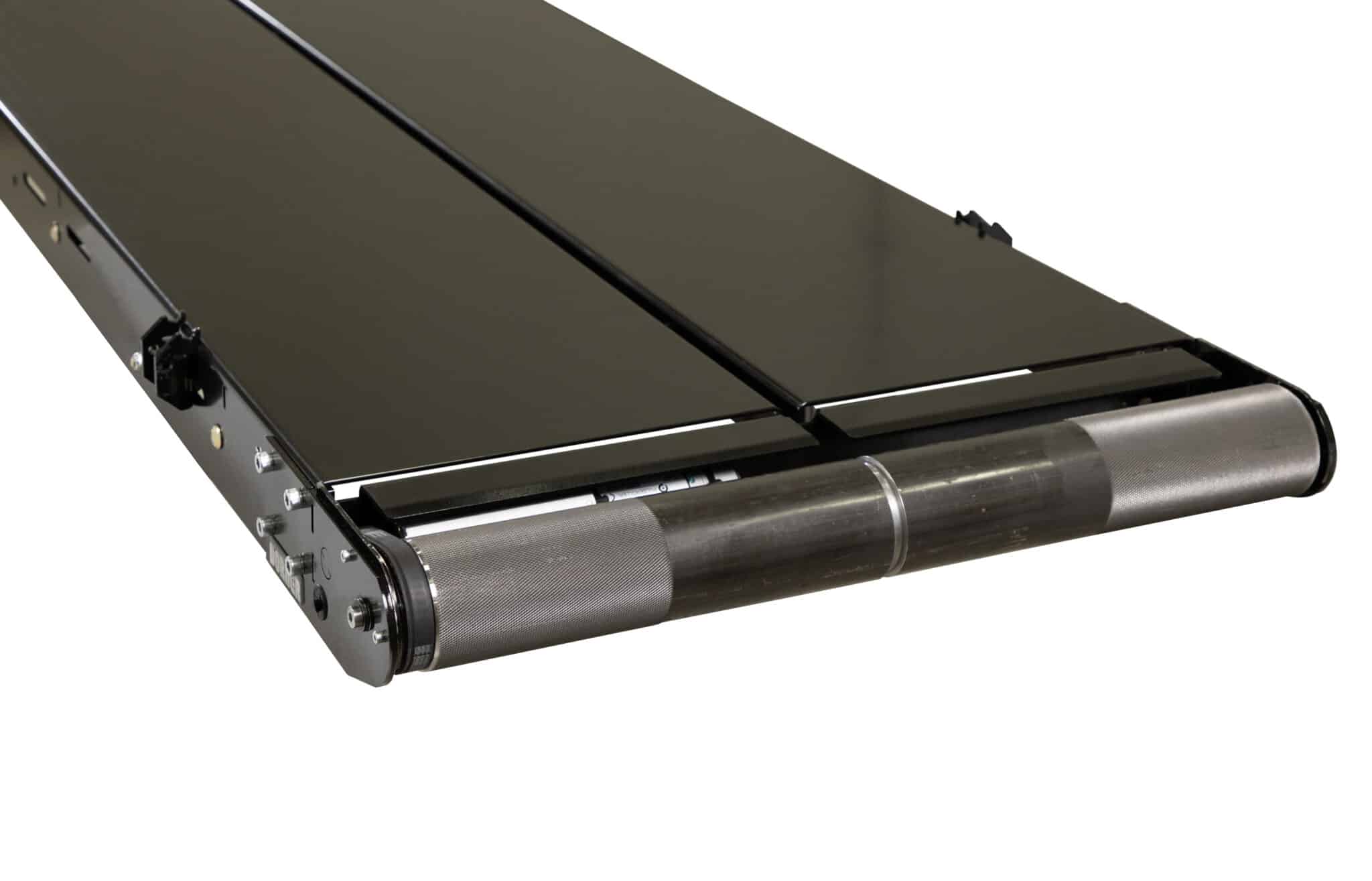

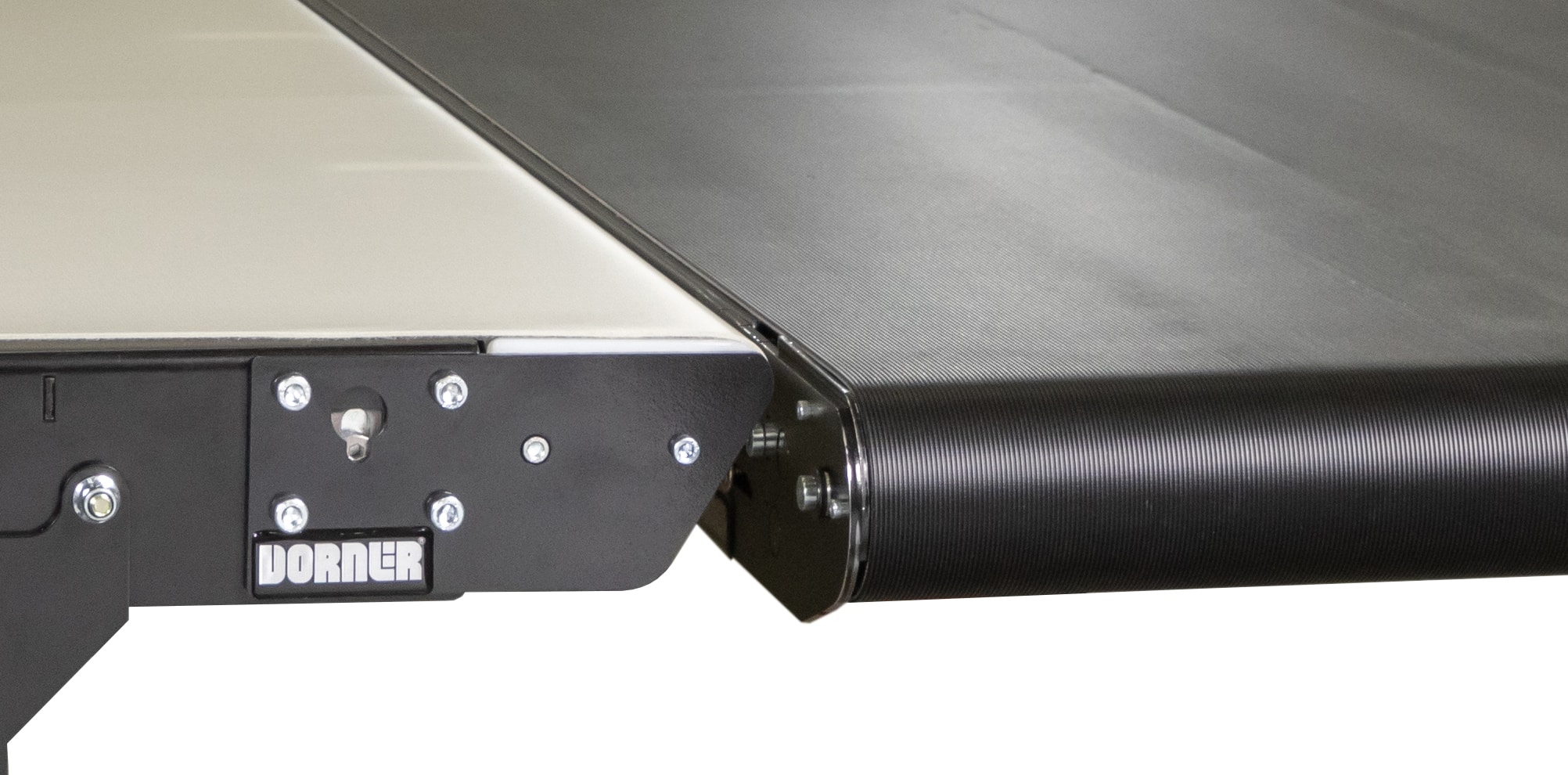

The DCMove Belted Conveyor features an economic painted steel frame with options for a variety of fabric or rubber belting. This new conveyor system is also built with an internally mounted motor within the tails, further reducing the conveyor’s footprint and providing an easy-to-integrate conveyor package. With a sleek, flush-sides design, the DCMove easily fits into tight spaces and maximizes belt coverage.

In combination with Dorner’s v-guided belt tracking and precise rack and pinion belt tensioning, the features of the DCMove Belted Conveyor will better serve the logistics, e-commerce, and material handling industries.

Product Features

- Painted steel construction for most cost competitive package movement

- V-guide belt tracking and easy belt tensioning

- Maximized belt widths and load capacity

- Sealed for life internal bearings

- Most compact conveyor drive package. Internal gearmotor allows the conveyor to fit in tight spaces

General Specifications

- Flat and cleated belt options

- Flat belt includes end drive, center drive, and internal motor mounting packages

- Lengths from 960 to 12,000 mm (38 in to 40 ft)

- Belt widths from 254 to 1,219 mm (10 in to 48 in)

- 76 mm (3 in) roller diameters with 32 mm (1.25 in) nose bar option to handle smaller packages

- Loads up to 181 kg (400 lbs)

- Speeds up to 183 m/min (600ft/min)

DCMove Belted Conveyor Applications:

- Distribution Center Product Sorting

- Packaging

- Palletizing

- Industrial Material Handling

- Automated and Manual Assembly

Manuals & Literature

Looking for Service Manuals? Search for Service Manuals by part number or product type HERE.

| Engineering Manuals | Pages | File Size |

| DCMove Series Engineering Manual | 50 | 6 MB |

| Literature | Pages | File Size |

| DCMove Series Conveyors Brochure | 4 | 2 MB |

Accessories

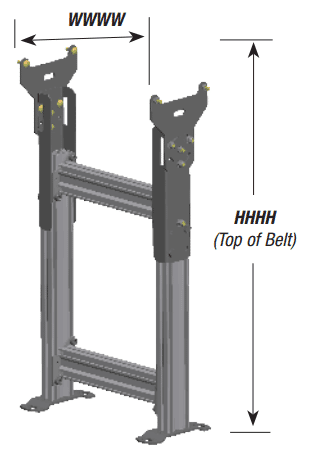

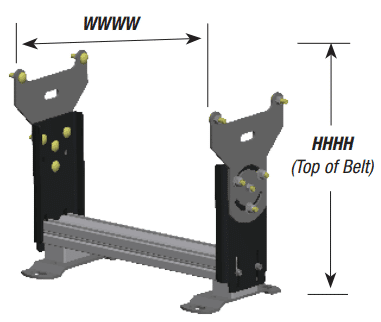

Support Stands

Fixed Height Support Stand |

Short Support Stand |

|

|

* Outrigger is used when conveyor height to width ration exceeds 3.5, and on side drive motor mount packages. |

|

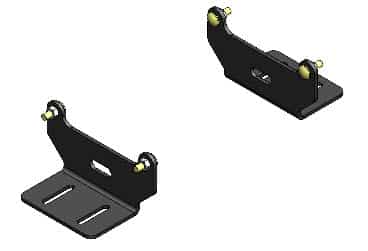

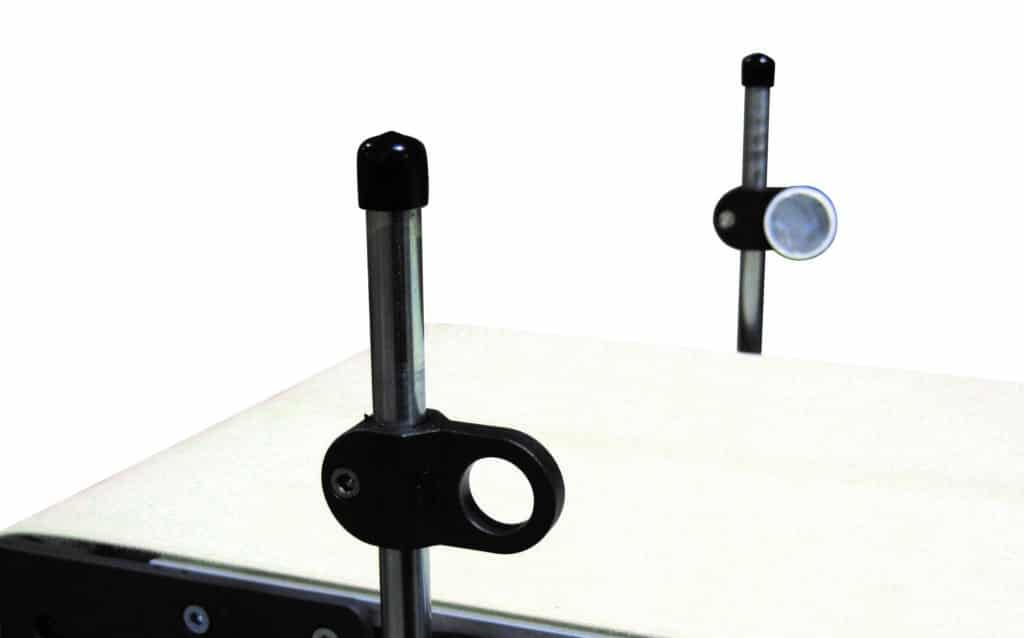

Brackets

Tabletop Bracket |

Photo Eye Bracket Kits |

|

|

|

|

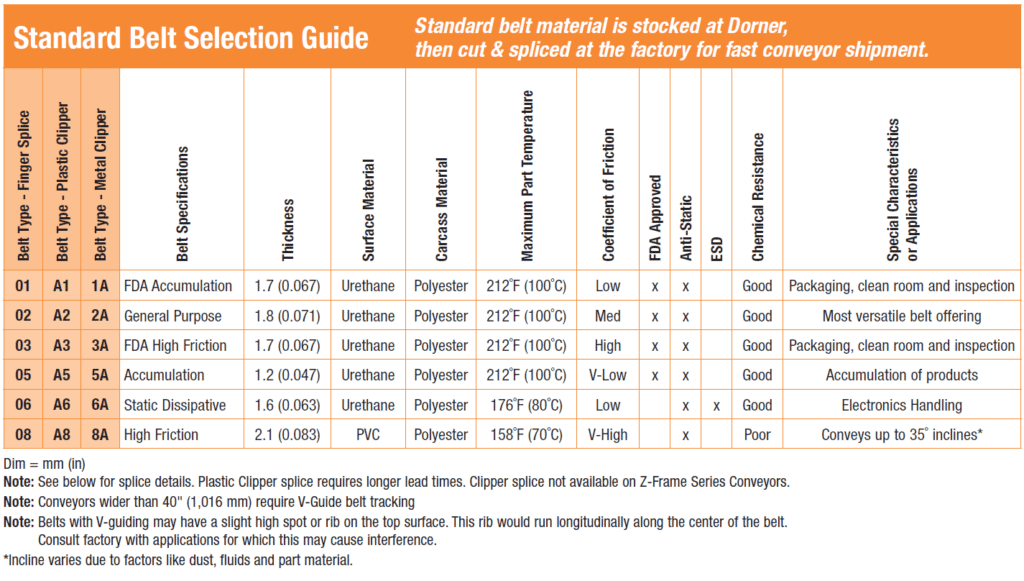

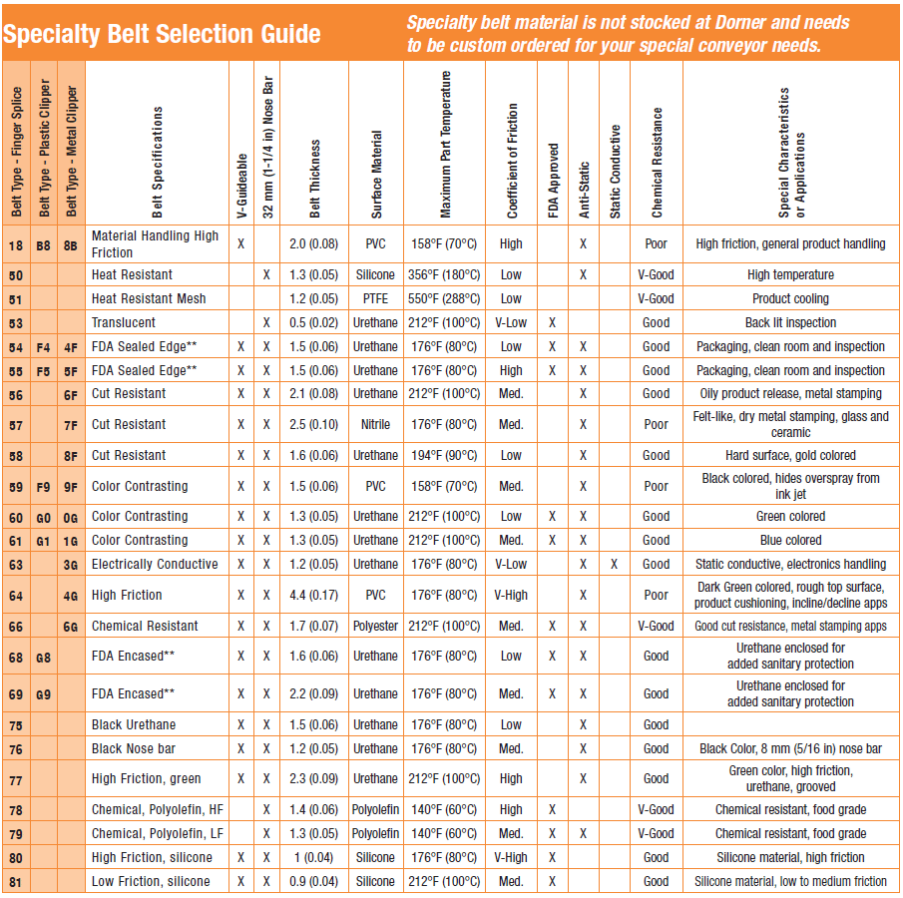

Belting

Belt Types

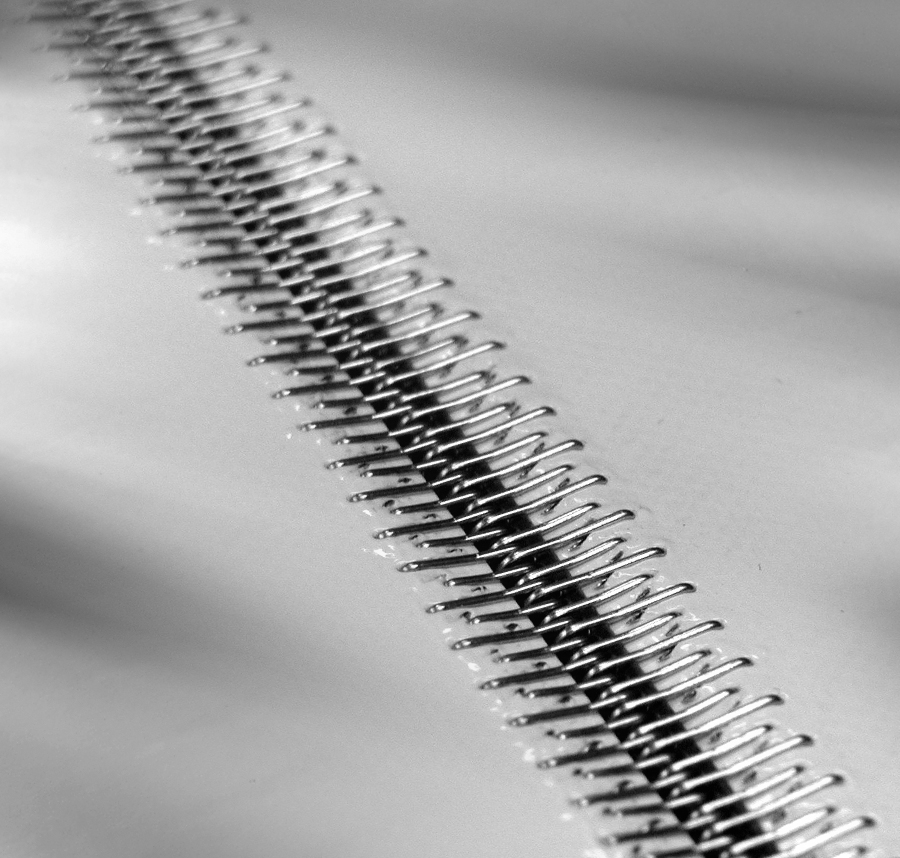

Belt Splice

Finger Splice |

Plastic Clipper** |

Metal Clipper** |

|

|

|

| All belts are available with a standard Thermoformed finger splice. This splice makes the belt continuous and is virtually undetectable. Splice bonding methods vary by belt type. Consult factory for details. | An optional plastic clipper splice is available for quick removal of belts or when conveyors are installed in tight spaces. The clipper does not protrude above the belt surface. | An optional metal clipper splice is also available for quick removal of belts or when conveyors are installed in tight spaces. |

Plastic and Metal Clippers are slightly thicker than base belt. Contact factory for details.

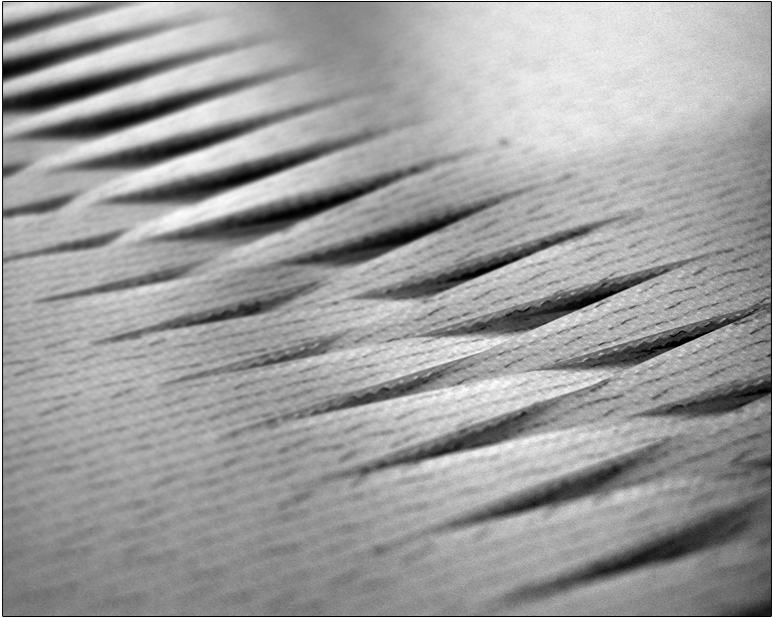

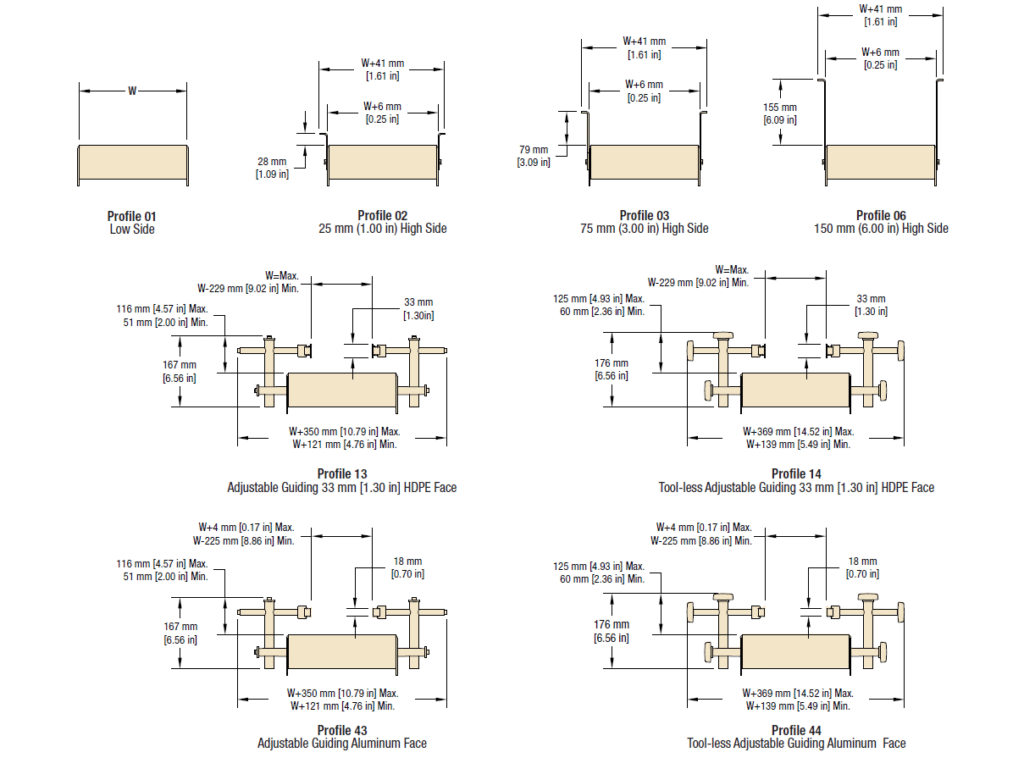

Profiles

DCMove Flat Belt Profiles

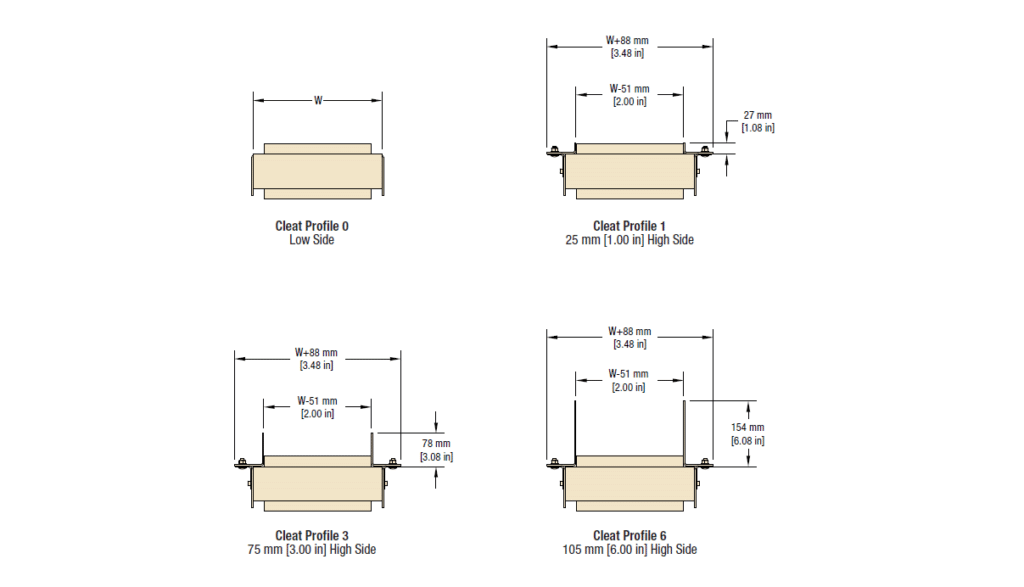

DCMove Cleated Belt Profiles

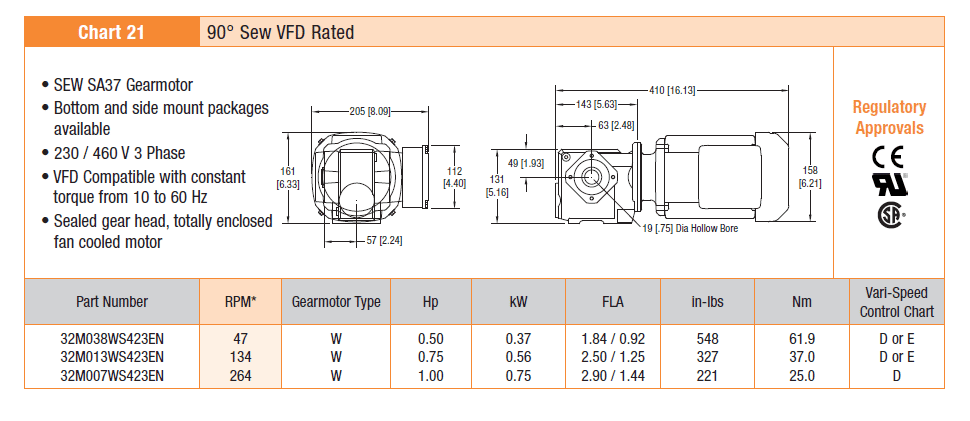

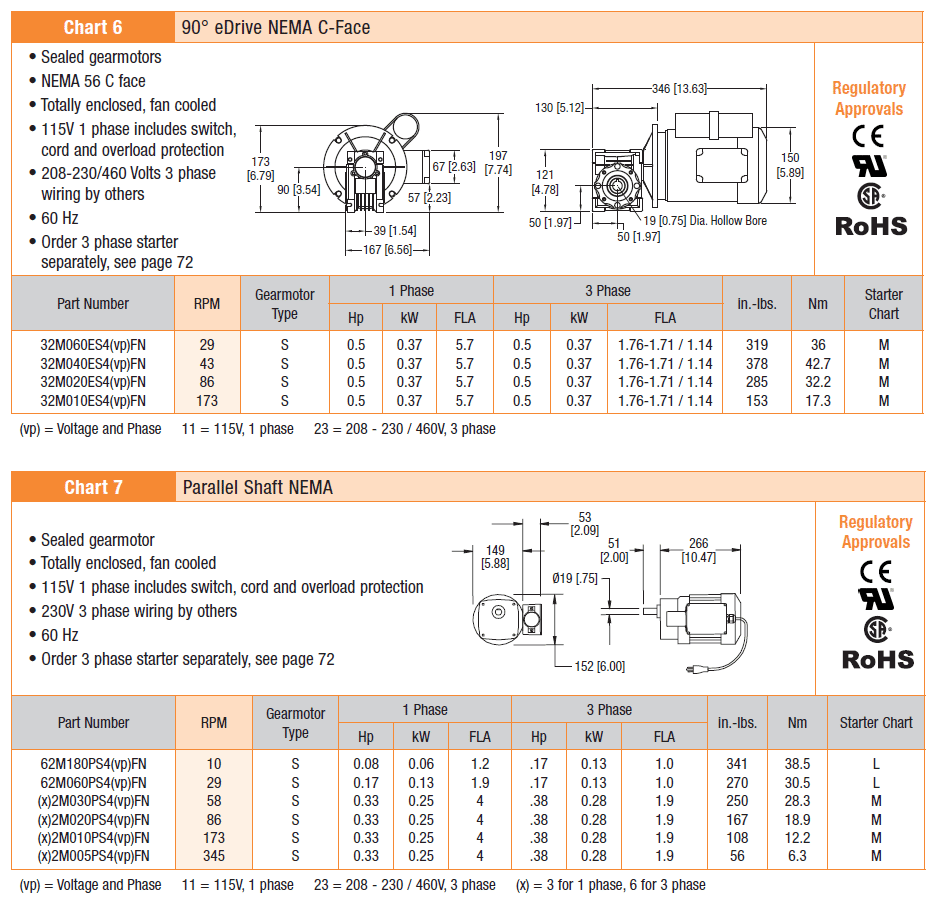

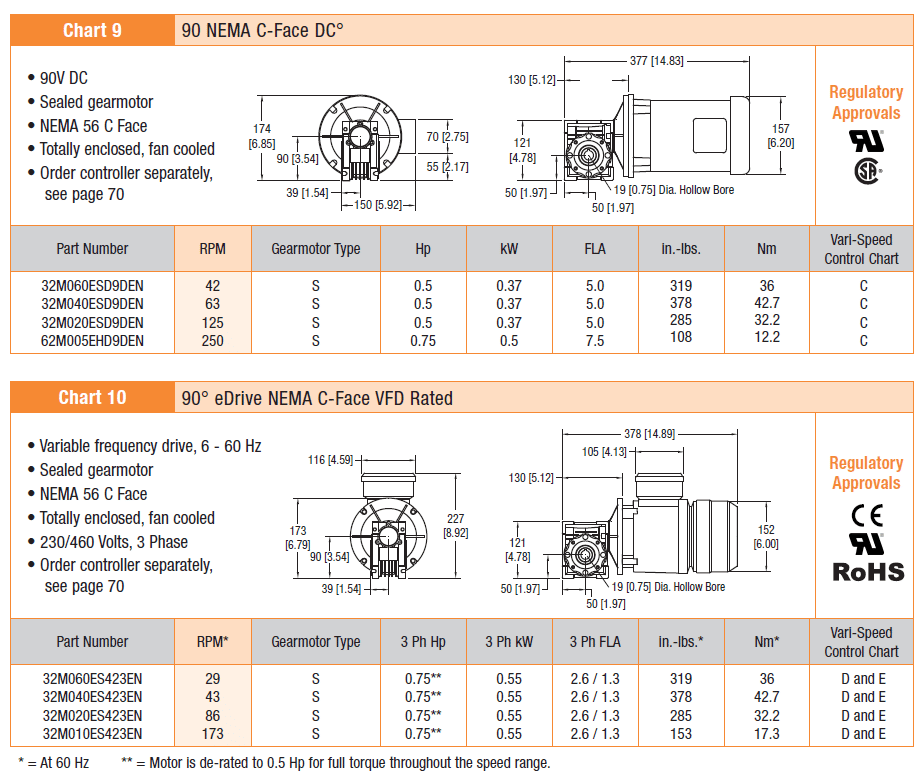

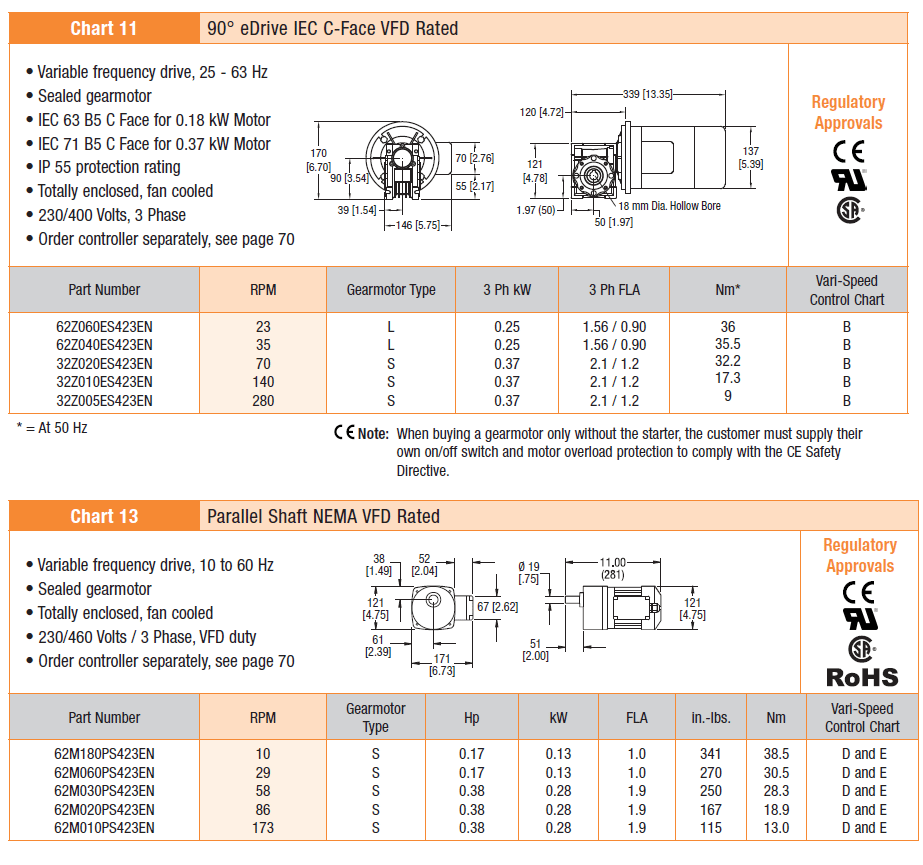

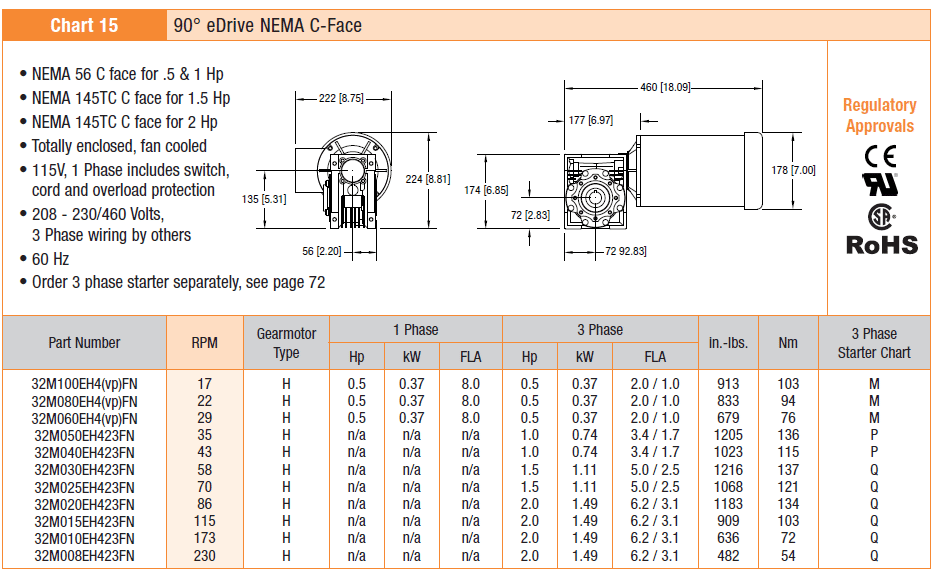

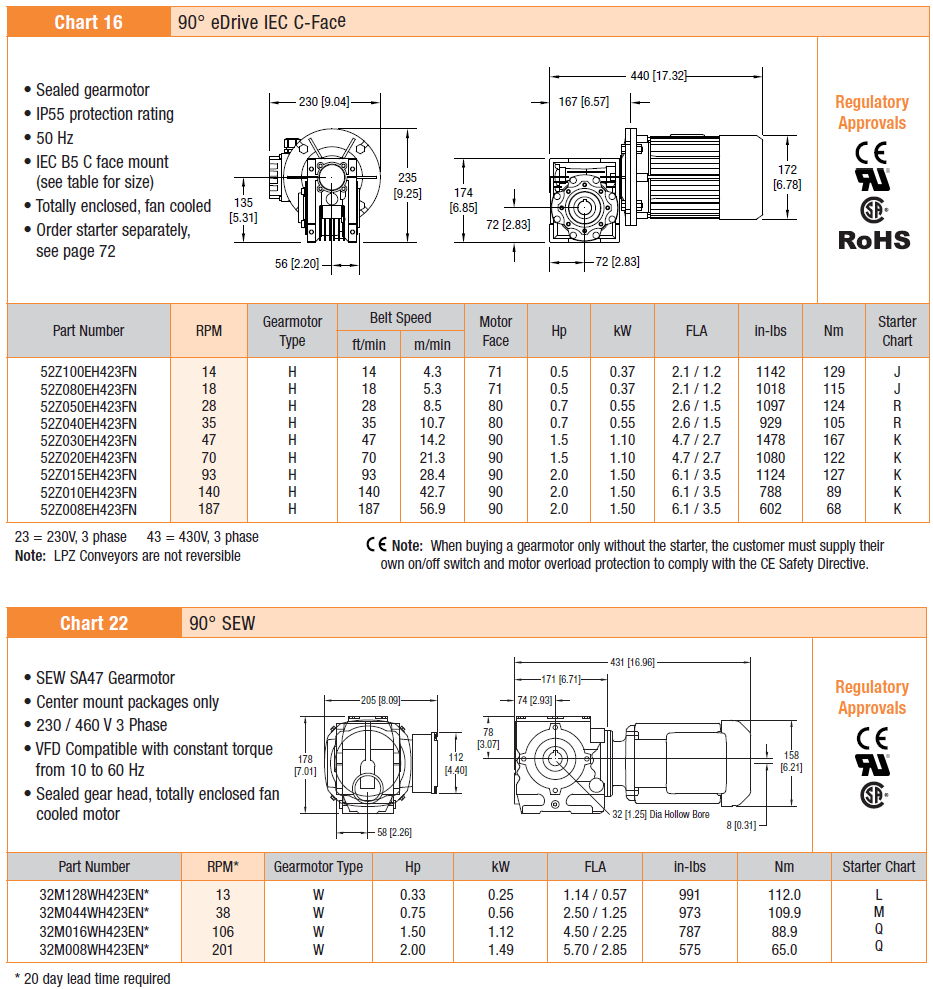

Gearmotors

Standard Duty Gearmotors

Standard Load, Fixed Speed

FLA = Full Load Amperes

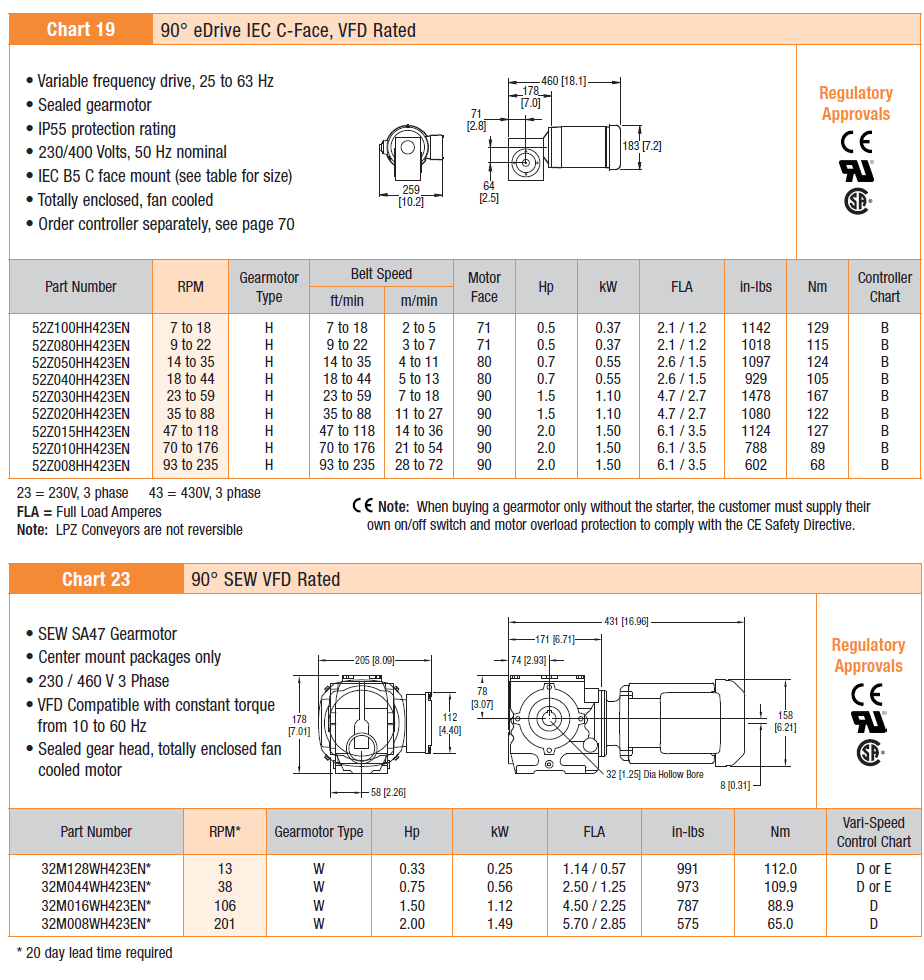

Some motors and gear reducers may normally operate hot to the touch. Consult factory for specific operating temperatures. Note: Dimensions = mm (in)

Standard Load, Variable Speed

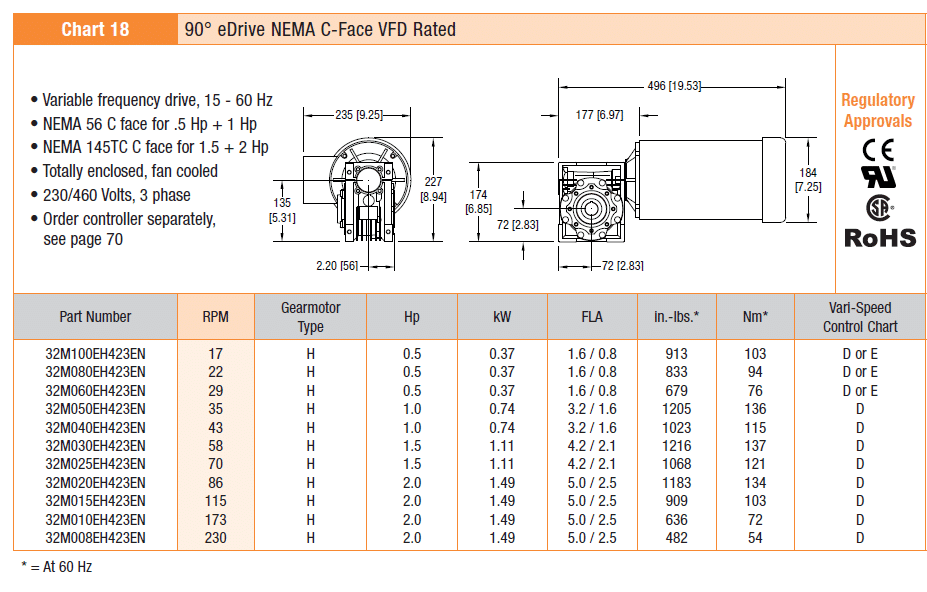

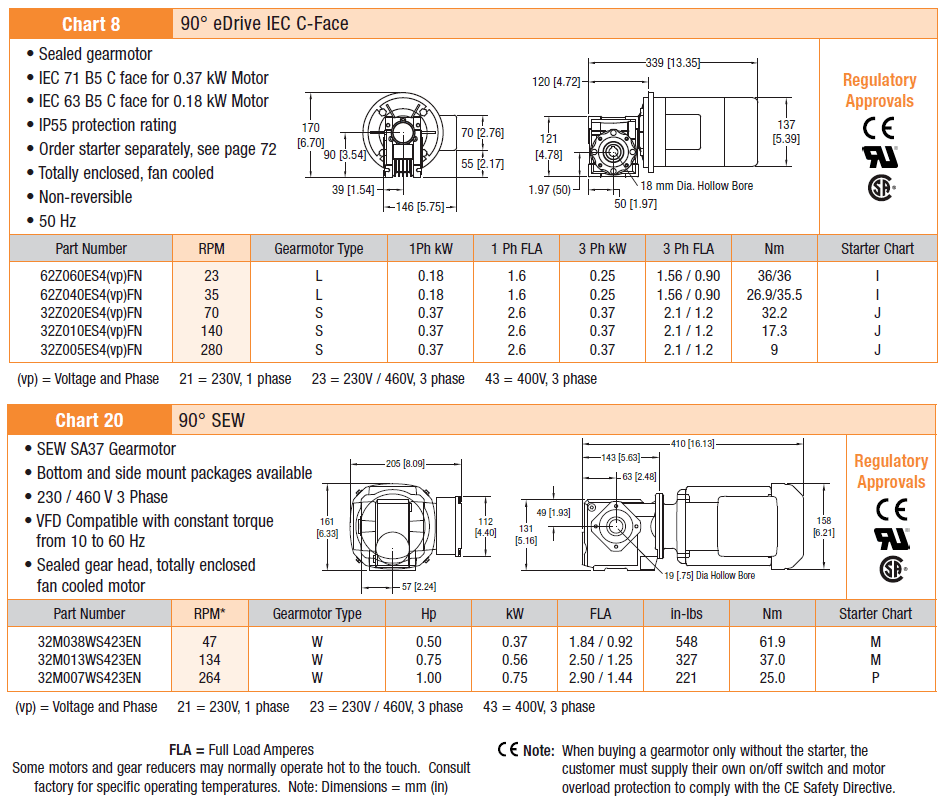

Heavy Duty Gearmotors

Heavy Load, Fixed Speed

FLA = Full Load Amperes

Some motors and gear reducers may normally operate hot to the touch. Consult factory for specific operating temperatures. Note: Dimensions = mm (in)

Heavy Load, Variable Speed

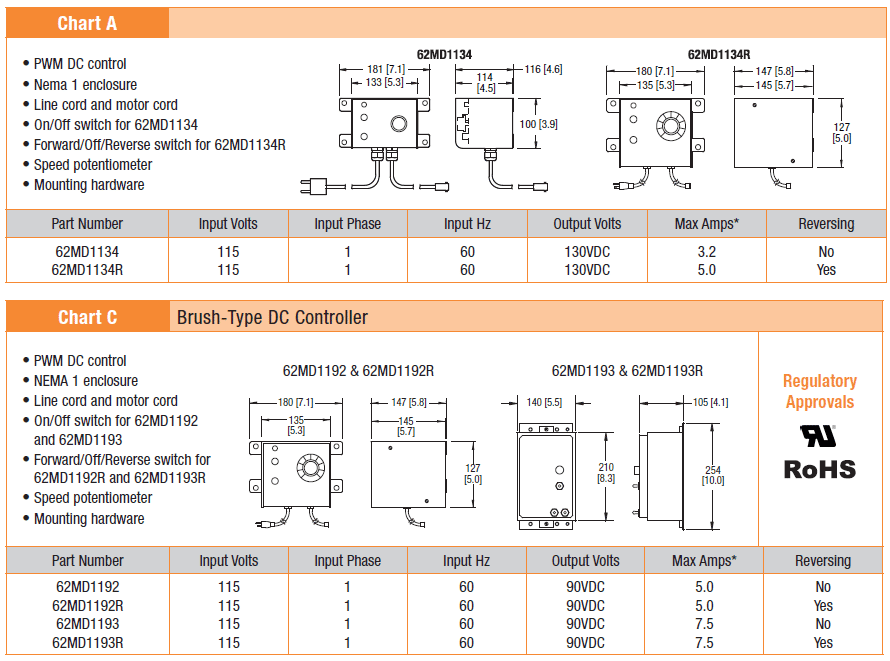

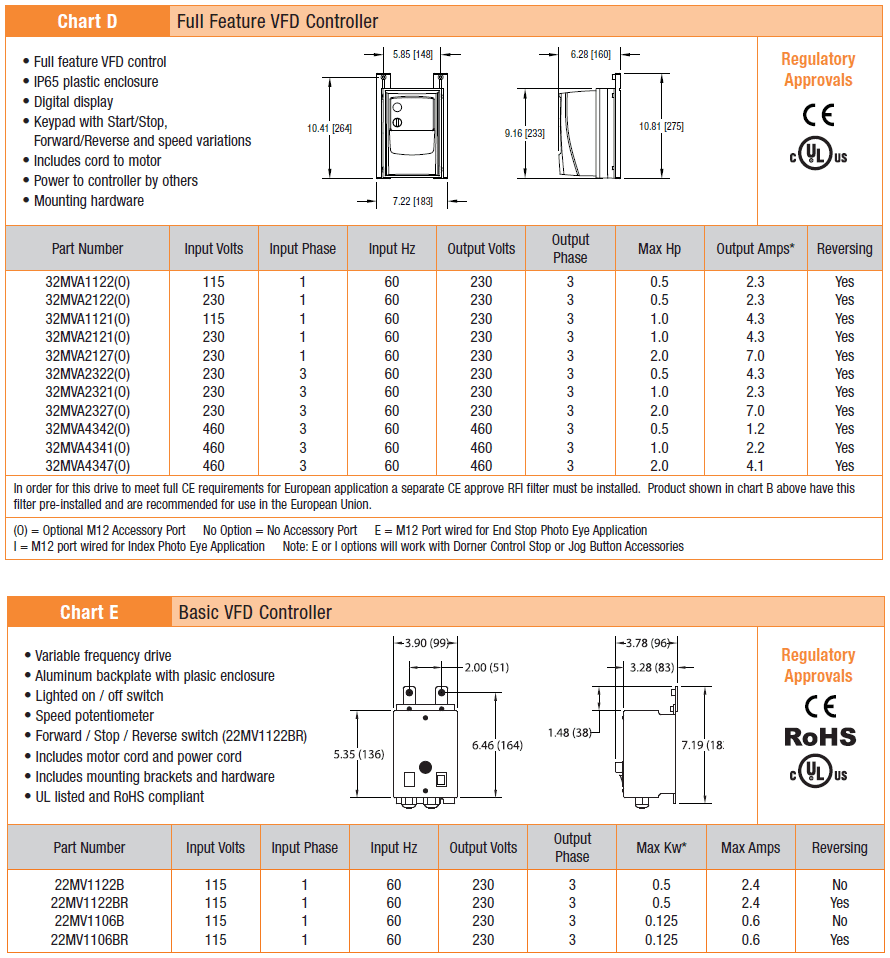

Variable Speed Controllers

* = See FLA from motor charts Note: Dimensions = mm (in)

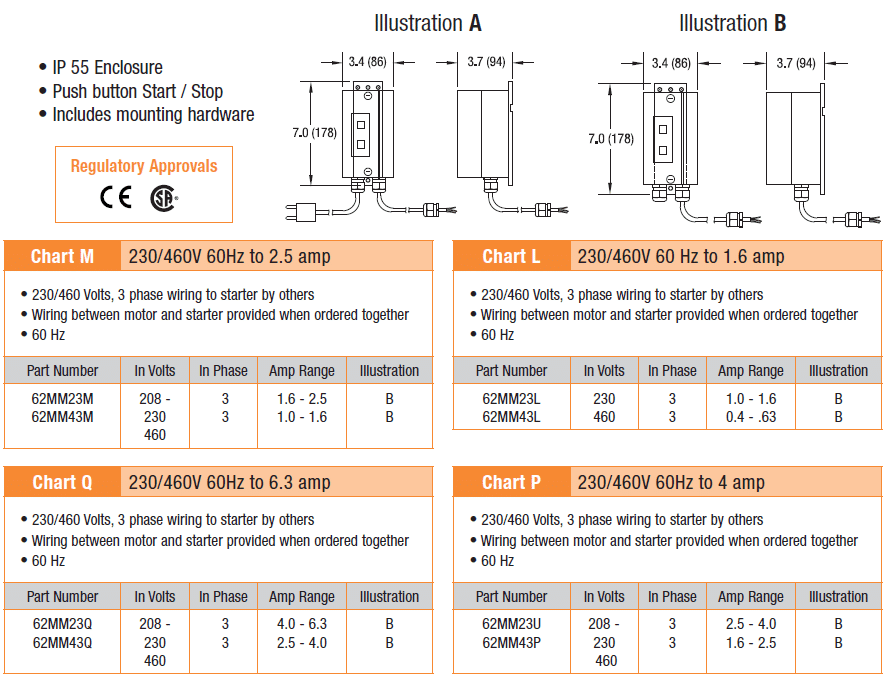

Manual Motor Starters

are required by the National Electric Code (NEC) for safe motor operation.

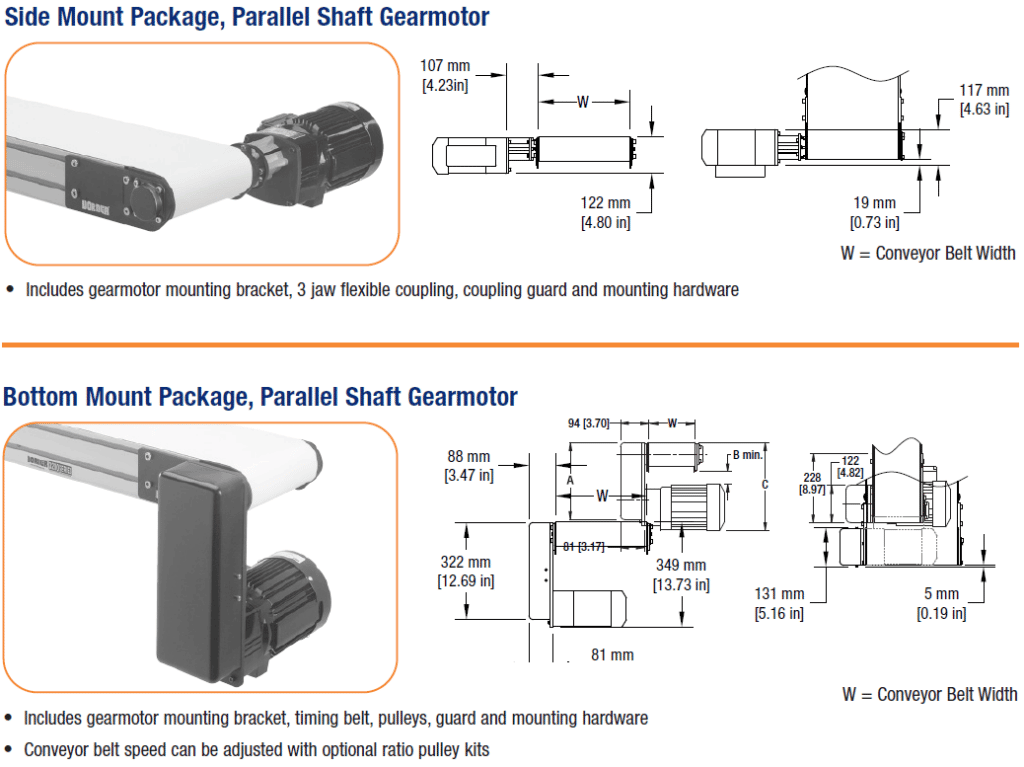

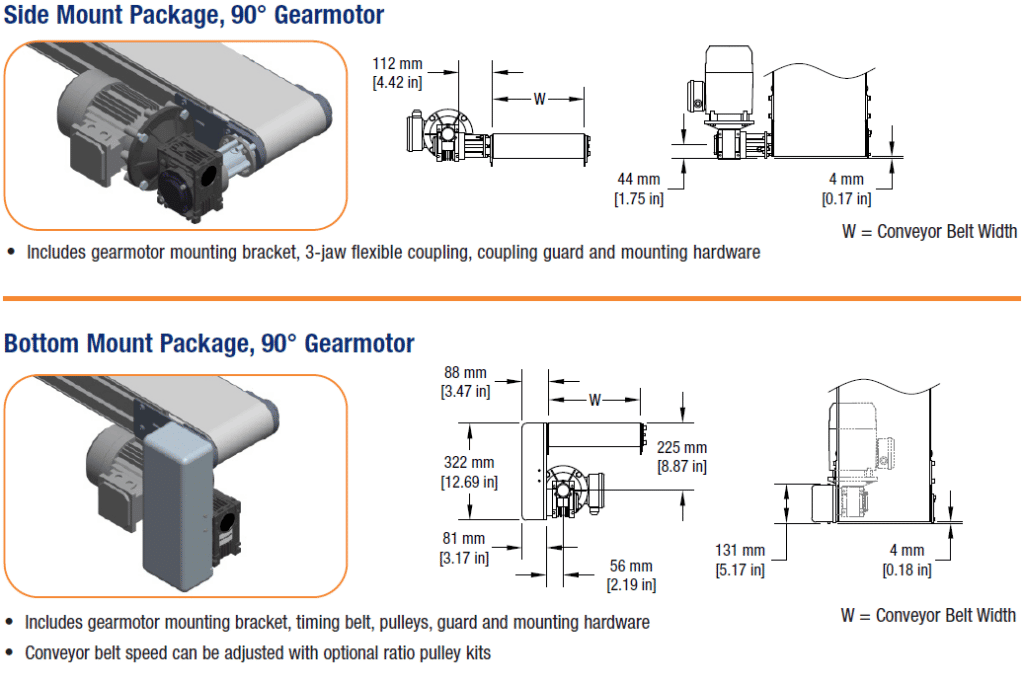

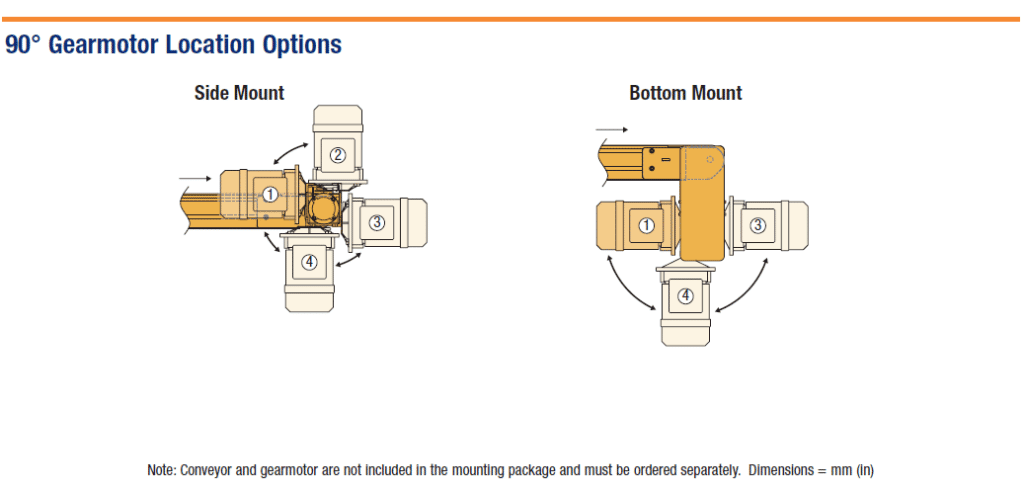

Drive Mounting Packages

Drive Mounting Packages

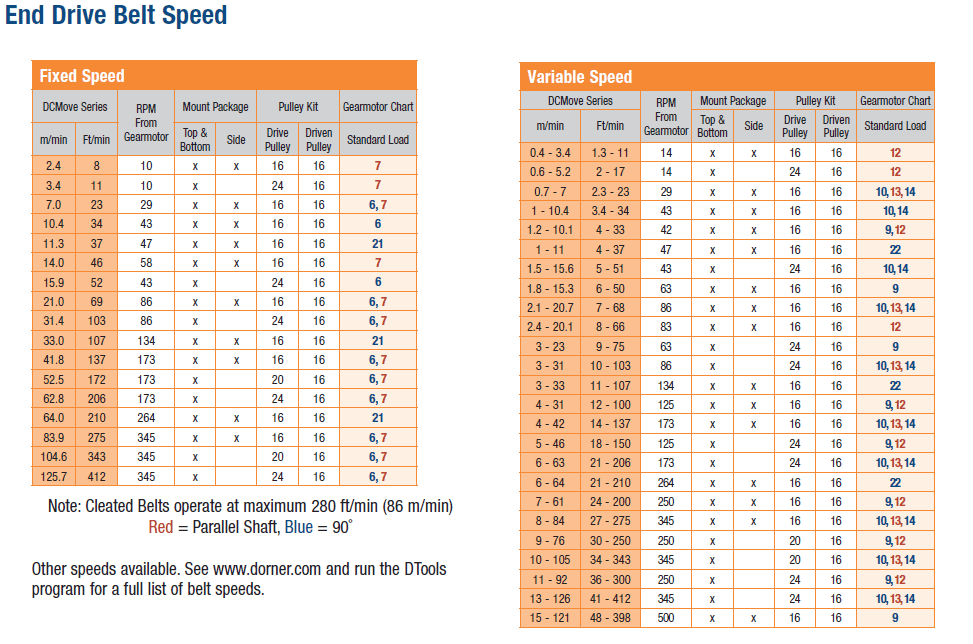

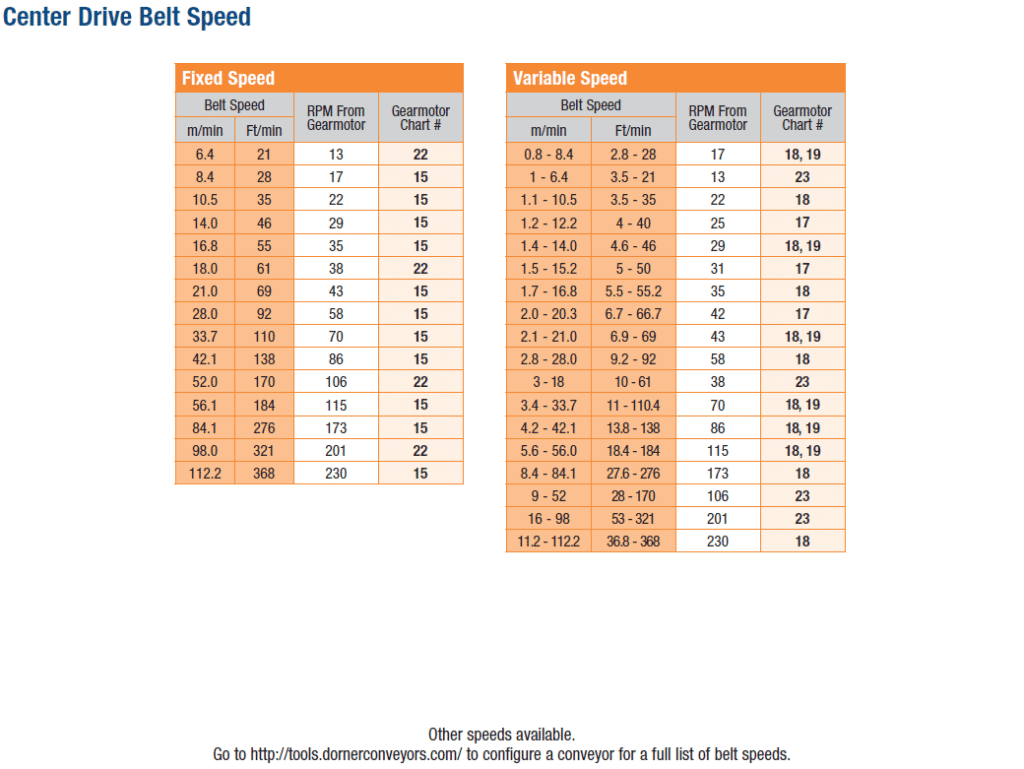

Drive Speed